Trust_Uploader

Active Member

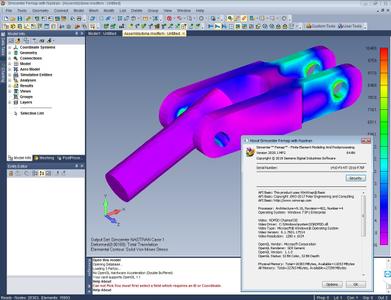

Siemens Simcenter FEMAP 2020.1.2 with NX Nastran | 2.3 Gb

Languages: 中文 (Simplified), 中文 (Traditional), English, Deutsch, 日本語

Siemens PLM Software pleased to announce the release of Simcenter Femap version 2020.1.2. This latest release provides a variety of improvements that will help your productivity across the simulation workflow.

Updates and Enhancements

Interfaces - Simcenter Nastran (formally NX Nastran)

SOL 401 and 402 Only

- Added support for reading plastic strain results at grid points for SOL401/SOL402. This includes support for solid and shell elements.

SOL 402 Only

- Added support to write request to recover Elastic Strain output at grid points for SOL402.

Output and Post-Processing

- Added support for post-processing plastic strain results at grid points for SOL401/SOL402. This includes support for solid and shell elements.

Corrections

Analysis Manager

- Corrected issue with the "Boundary Conditions" dialog box in the Master Case of Buckling Analysis for Nastran solvers which could cause FEMAP to exit unexpectedly. (PR# 9682285)

Geometry

- Corrected issue which caused some surfaces to not be offset correctly. In addition, some additional warning messages were implemented to potentially alert the user to review the offset surface(s) before meshing.

Graphics

- Corrected issue which caused a very large amount of memory to be used to display mesh size symbols on curves, which now allows a neutral file to properly imported. Please note, an issue still exists when the default point size is too small, causing a massive amounts of curve mesh evaluation and causing a degradation in performance.

Interfaces - Nastran

- Corrected issue introduced in FEMAP v2020.1 that caused the "BOLTFRC" entry to be written for versions of Nastran (i.e., Autodesk Nastran) where it is unsupported. This issue also prevented the correct entry, "BOLTFOR", from being written for those versions of Nastran.

Interfaces - Simcenter Nastran (formally NX Nastran)

SOL 401 and 402 Only

- Corrected issue that affected the writing of the "BCSET" case control command for SOL401/SOL402. Contact cannot be changed in a modal subcase, or set if that subcase is the first in the analysis OR not sequentially dependent, thus the "BCSET" case control command is prevented from being written in these special cases.Corrected issue which caused erroneous "TEMP(LOAD)" case control to be exported for SOL401/SOL402 when the "From Load Set" option was selected in the Temperature drop-down, even if the load set selected did not contain any temperature loads.

SOL 402 Only

- Corrected issue which caused an invalid value to be written for the MATSYM parameter on the NLCNTL2 entry for SOL 402. The Simcenter Nastran Quick Reference Guide mentions using "YES" or "NO" for this parameter, but Nastran actually accepts only "1" or "0".

Interfaces - ABAQUS

- Corrected issue when exporting directional pressure loads as DLOAD, type TRVEC on plate elements which would cause "TRVEC" to be written twice to the TRVEC data line (i.e., TRVECTRVEC) when analysis type is Frequency Response.

- Corrected issue when exporting directional pressure loads as DLOAD, type TRVEC on axisymmetric shells and plane strain elements where 2 TRVEC data lines would be printed for a single load for all analysis types other than Frequency Response.

Properties

- Corrected issue with Beam and Bar properties when Shape was set to NASTRAN T2 in the Cross Section Definition which could cause incorrect values to be calculated for Torsional Constant, Y Shear Area, and Z Shear Area.

Meshing

- Corrected issue which occurred when attempting to extrude elements or project nodes along a vector or using an element's normal direction. Previously, if the vector supplied by the user or the normal vector missed the edge of the surface due to numerical tolerances, the commands or API methods would fail or generate inconsistent results. Now, assuming the vector passes within numerical tolerances of the edge of the surface, the process should work consistently. In addition, corrected similar issues when attempting to project points.

API

- Corrected issue which caused deleted output vectors to be listed, one-at-a-time, to the specified List Destination(s) when using feDeleteOutputV2 or feDeleteOutput2V2.

x Siemens Simcenter FEMAP 2020.1.2 with NX Nastran

Close

Simcenter Femap is a finite element modeling and post-processing environment. It interacts with solvers such as Nastran to model physical behavior to assist in the drawing of conclusions about said behavior. Solvers typically require strict text file-based formatting of your analysis setup, which nobody does directly anymore. Instead, programs such as Femap are used to prepare those text file inputs to the solver using a combination of a modern graphical user interface built-in functions to automate tedious tasks.

Simcenter Nastran is a separate "solver" product that is usually bundled within Femap. Simcenter Nastran (formerly NX Nastran) is an actively-developed offshoot of the Nastran code base, but is one of the most common solvers for finite element analysis (FEA). Nastran is essentially the math behind FEA. As a pre-processor, Femap assists with building a model of a part, and then translates it into Nastran code. Nastran then computes the behavior. Following this, Femap reads the results and provides interpretation tools to facilitate the processing of output data. Oftentimes, the amount of information from the model is substantial, and Femap can enable a more rapid understanding of gross behavior.

Short video showcasing new capabilities in Simcenter Femap 2020.1 around geometry editing.

Siemens PLM Software. a business unit of the Siemens Digital Factory Division, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, Siemens PLM Software works with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood.

Product: Siemens Simcenter FEMAP

Version: 2020.1.2 (2020.1 MP2) with NX Nastran

Supported Architectures: x64

Website Home Page : Language: 中文 (Simplified), 中文 (Traditional), English, Deutsch, 日本語

System Requirements: PC *

Supported Operating Systems: *

Size: 2.3 Gb

Welcome to FEMAP! This document will help you to setup your computer so that you can immediately begin to explore the many capabilities of FEMAP.

This document contains information specific to getting started on a PC, which includes 64-bit versions for Windows 7, Win-dows 8, Windows 8.1, and Windows 10.

The FEMAP installer contains only the 64-bit version of FEMAP, as a 32-bit version is no longer available.

Hardware/Software Requirements

There are no special hardware/software requirements for FEMAP beyond those imposed by the Windows operating systems. There are many types of hardware that will allow you to use FEMAP. Proper choice of hardware, however, can often make the difference between frustration and productivity. Here are a few suggestions:

- Memory, RAM

- Memory, (Hard Disk)

- Graphics Boards

-Abaqus ODB Requirements

Memory, RAM

You will need at least 128 Mbytes of RAM to run FEMAP and the Parasolid solid modeling engine, which is the default. Obviously, the more amount of RAM the better. Adding RAM can be one of the most cost effective means of increasing per-formance.If using the "Standard" geometry Engine in FEMAP, you can actually run with as little as 32 Mbytes of RAM. This is not a recommended configuration.

Memory, (Hard Disk)

Required hard disk space is very difficult to estimate, but in general you will never have enough. Analysis results will be the main driver of any disk space requirement. Models are typically relatively small. A model with 1000 nodes and 1000 ele-ments would typically be less than 1 Mbyte in size. Output from an analysis of that model, however, could be 5 Mbytes, 10 Mbytes or even larger, depending on the output you request. To estimate total disk space, you need to first estimate how many models you will have on-line simultaneously, the approximate size of those models, and the type of output you will request. It is recommend to have as much disk space as budget will allow, as each version of FEMAP can support larger and larger models, which in turn create larger and larger amounts of output.

Graphics Boards

While, standard graphics adapters may work very well with FEMAP, having a specialized board with support for OpenGL will provide increased graphical performance when dynamically rotating large, complex models. They also usually provide higher resolution and more colors, which make graphics easier to see and more realistic. Also, in order to use the "Perfor-mance Graphics" option, a graphics card which supports OpenGL 4.2 is required.

Recommend Download Link Hight Speed | Please Say Thanks Keep Topic Live